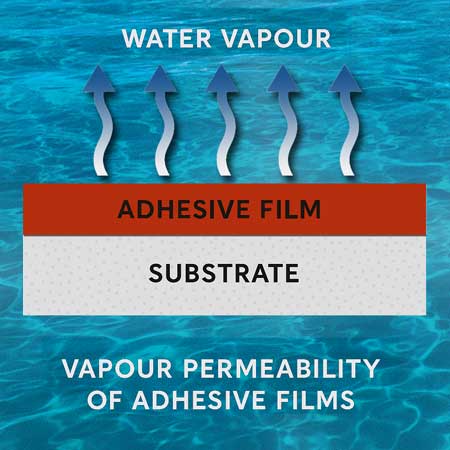

Vapour permeability measurement is a critical parameter in relation to adhesive films across a range of industries. It determines how much vapour, usually water but other gases in some applications, can pass through a material over time, which directly impacts performance in applications where moisture control is essential.

Vapour permeability measurement is a critical parameter in relation to adhesive films across a range of industries. It determines how much vapour, usually water but other gases in some applications, can pass through a material over time, which directly impacts performance in applications where moisture control is essential.

Industries Using Vapour-Permeable Adhesive Films

1. Medical and Healthcare

2. Construction

3. Packaging

4. Electronics

5. Textiles and Apparel

Key International Standards

Here are some internationally recognised standards relevant to vapour permeability of adhesive films:

Method |

Principle |

Units |

Typical Applications |

Relevant Standards |

Instrumental method |

Numerous sensor types are available including mass spectrometry |

g/m²/day |

Woks well across all applications for material samples as well as components |

Chris, what would you say are the main ones? |

Coulometric Sensor (Modulated Humidity) |

Detects water vapour passing through the sample using a sensor that quantifies moisture content in nitrogen gas. |

g/m²/day |

Barrier films in electronics, pharma packaging |

ISO 15106-3 |

Infrared Detection (IR Sensor) |

Measures the water vapour using an IR beam absorbed by moisture molecules in a test chamber. |

g/m²/day |

High-barrier packaging films, multilayer laminates |

ISO 15106-2 |

Electrolytic Sensor |

Vapour passes through film and is absorbed in phosphorus pentoxide, creating an electrical current. |

g/m²/day |

Pharmaceuticals, sensitive electronics packaging |

ISO 15106-1 |

Dynamic Vapour Sorption (DVS) |

Measures the change in mass as a film sample is exposed to different humidity levels in a controlled environment. |

µg/s or % RH over time |

Advanced materials research, high-precision measurements |

No single WVTR-specific standard, but widely used in research |

Gravimetric (Desiccant or Water Method) |

Measures weight change over time due to vapour transfer across a film sealing a cup of desiccant (or water). |

g/m²/day |

Construction membranes, packaging, medical dressings |

ASTM E96 (Desiccant & Water Method), BS 3177 |

Isostatic Humidity Cell (Upright Cup Test) |

Variation of gravimetric method with fixed humidity on both sides and no desiccant. |

g/m²/day |

Membranes in textiles and breathable films |

Often referenced in building codes, or derived from ASTM E96 |

Summary

Vapour permeability measurement of adhesive films is vital across many industries for controlling moisture without sacrificing barrier integrity. From medical devices to construction and food packaging, understanding and controlling this property ensures product safety, performance and comfort.